WET MOTOR: Efficiency, Durability, and Sustainability for Critical Operations

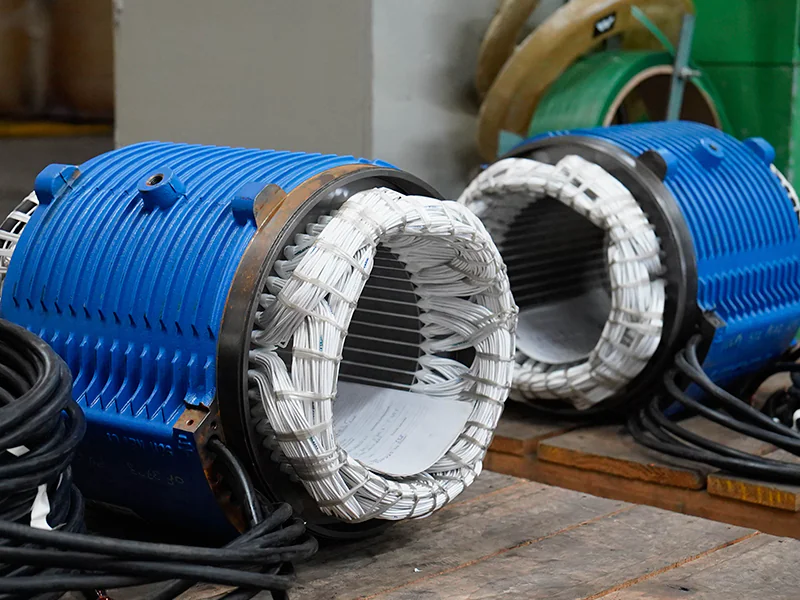

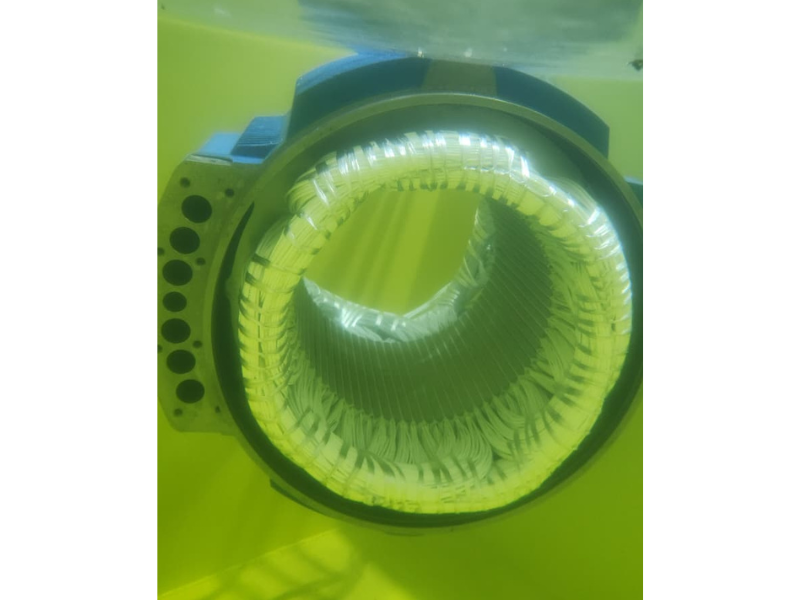

In the world of industrial pumping, where efficiency and reliability are crucial, HIGRA MINING brings the pioneering advancement of the wet motor. This innovative solution, used in well-known equipment like our Amphibious Pumps, eliminates the use of oil and maximises performance. Unlike conventional motors, the wet motor operates with its components fully immersed in clean water, ensuring direct cooling and continuous lubrication. This technology is vital for demanding mining and steel operations, as it guarantees thermal stability even under continuous operation and in aggressive environments, thus optimising productivity and safety.

Innovative Advantages and Operational Impact

The integration of cooling and lubrication into a single fluid drastically simplifies maintenance and enhances operational reliability. With a hermetic seal and high-performance materials, the HIGRA Mining wet motor offers:

Greater Energy Efficiency: It reduces power consumption by avoiding thermal losses, which is crucial for systems that operate for long periods in pits, dams, or industrial processes.

Extended Service Life and Low Wear: Constant immersion minimises friction and thermal stress, ensuring exceptional durability.

Reduced Clogging and Maintenance: The innovative design prevents particle build-up, making it ideal for handling sludge, effluent, and water with suspended solids.

Clean and Safe Operation: The absence of oil eliminates the risk of environmental leaks, simplifying permits and protecting sensitive ecosystems.

Robustness and Reliability: It operates with stability in severe conditions, ensuring production continuity in critical applications.

Commitment to Sustainability and Proven Performance

The adoption of the wet motor reinforces HIGRA MINING’s commitment to robust and sustainable solutions, aligned with the industry’s best ESG practices. This technology, validated by rigorous testing in our Hydro-energetic Testing Laboratory, allows our equipment to operate in its ideal efficiency range with lower energy consumption. Whether for any model of our versatile Amphibious Pumps, the wet motor is the heart of systems that deliver high performance, reliability, and low operational cost for the challenges of global mining and steelmaking.

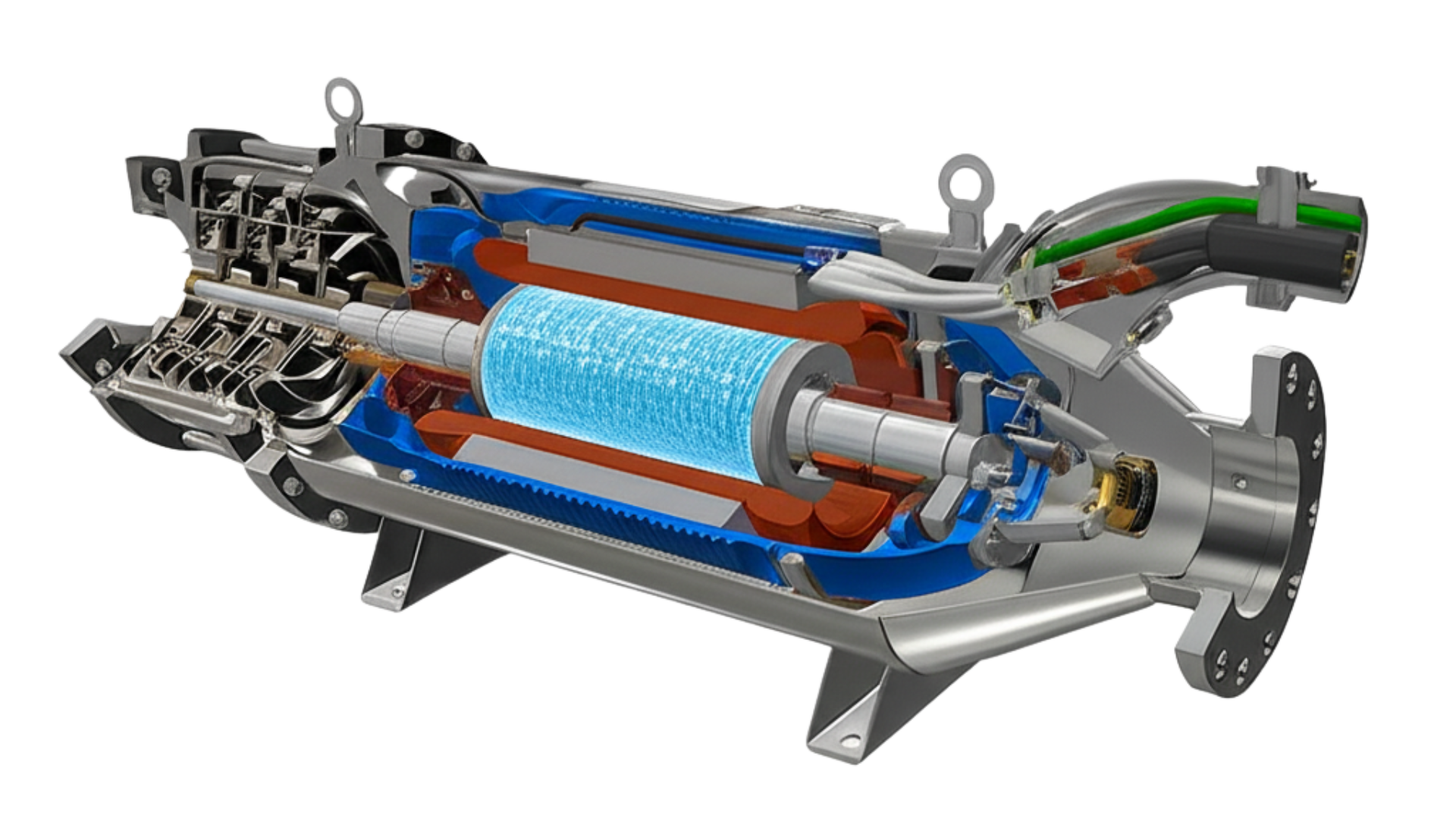

Monoblock Amphibious Pump: The Structure of Reliability for Severe Environments

In the high-demand and critical environment of mining and steelmaking, equipment reliability is non-negotiable. HIGRA MINING’s Amphibious Pumps stand out for their innovative monoblock structure: the pump and motor are united in a single assembly. This integration eliminates the main Achilles’ heel of conventional systems—misalignment between components—ensuring superior performance, maximum robustness, and a significant reduction in unplanned downtime in the field.

In traditional pumps, misalignment causes premature part wear, excessive vibration (increasing noise and compromising structures), and higher energy consumption, which culminates in elevated maintenance costs and the risk of critical operation interruptions. The HIGRA MINING monoblock solution overcomes these challenges. Thanks to the single shaft and simplified assembly, we guarantee zero need for alignment, reduced failures, optimised installation costs, and enhanced safety in extremely severe environments, like those found in mining (dewatering, pit drainage) and steelmaking (processes).

Ready to optimise your processes?

Contact our team to receive a full consultation for your project. We are ready to understand your challenges and design the ideal amphibious solution for your operation.

Optimizing Flows. Conquering the Impossible. Higra Mining.

Higra Mining Montadora - SC

Rua Alvaro Beraldi, 461

Carvalho, Itajai – SC

CEP: 88.307-740

Telefone: (47) 3690-0175

Email: contato@higramining.com.br

Higra Mining Service - SC

Telefone: (47) 99723-0185

Email: manutencao.servicos@higramining.com.br

Higra Mining Service - MG

Av. Canadá, nº 85, Jardim Canadá Nova Lima – MG, 34007-654

Higra Mining Service - PA

Av. Potigua, S/N – Quadra 55 –

Lt 18 e 19, Parque dos Carajás Parauapebas – PA, 68515-000